In the realm of packaging, precision measurements play a pivotal role in ensuring the quality and effectiveness of the packaging process. Understanding the significance of precise measurements is essential for achieving optimal results in packaging design and production. This guide will delve into the importance of precision measurements and provide valuable insights into perfecting your packaging through meticulous measurement practices.

The Importance of Precision Measurements

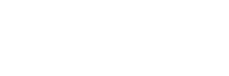

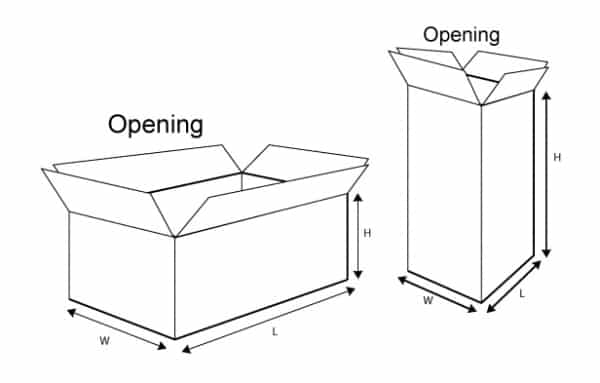

Accurate measurements are the cornerstone of successful packaging. They ensure consistency, reliability, and functionality in packaging design and production. Without precise measurements, packaging may be prone to errors, leading to inefficiencies, waste, and potential damage to the packaged product. Considering box dimensions during the design phase is crucial to accommodating the product securely and efficiently.

Benefits of Precision Measurements

- Consistency: Precise measurements facilitate consistent packaging results, eliminating variations and ensuring uniformity across production batches.

- Reliability: Accurate measurements enhance the reliability of packaging, reducing the risk of defects, leaks, or inadequate protection for the product.

- Efficiency: With precise measurements, packaging processes can be streamlined, reducing the time and resources required for production.

- Cost-Effectiveness: Precision measurements contribute to cost savings in packaging operations by minimizing material wastage and rework.

Tools and Techniques for Precision Measurements

Achieving precision in packaging requires the use of appropriate tools and techniques. Here are some essential resources and methods for accurate measurements:

- Calipers: Calipers are versatile tools for measuring dimensions such as length, width, and thickness with high precision.

- Micrometers: Micrometers are specialized instruments for measuring small distances or thicknesses with exceptional accuracy.

- Digital Scales: Digital scales provide accurate weight measurements, which are crucial for determining the appropriate amount of packaging materials.

- Coordinate Measuring Machines (CMM): CMMs offer advanced measurement capabilities, enabling precise dimensional analysis of packaging components.

- Statistical Process Control (SPC): SPC techniques help monitor and control packaging processes, ensuring consistency and quality through statistical analysis.

Precision Measurement Best Practices

To optimize packaging outcomes, adhere to the following best practices for precision measurements:

- Standardization: Establish standardized measurement procedures to maintain consistency and reliability in packaging operations.

- Training: Provide comprehensive training for personnel involved in measurement tasks to ensure accuracy and proficiency.

- Quality Control: Implement rigorous quality control measures to verify measurements’ accuracy and promptly identify any deviations.

- Documentation: For traceability and accountability, maintain detailed documentation of measurement data, including specifications, tolerances, and inspection records.

- Continuous Improvement: Continuously evaluate and refine measurement processes to enhance efficiency, precision, and packaging performance.

Bridging Precision Measurements with Packaging Design

Precision measurements into packaging design are essential for achieving optimal functionality and aesthetic appeal. By integrating accurate measurements from the outset, designers can ensure that packaging meets functional requirements and branding objectives. Key considerations include:

- Material Selection: Choose packaging materials with precise dimensional properties to accommodate product specifications and protect against external factors such as moisture, light, and impact.

- Structural Integrity: Design packaging structures with precise measurements to withstand transportation and handling while maintaining product integrity.

- Graphics Placement: Align graphic elements precisely to enhance the packaging’s visual impact and brand recognition.

- Ergonomics: To optimize user experience with precise measurements, consider ergonomic factors in packaging design, such as handle placement and opening mechanisms.

Conclusion

In conclusion, mastering precision measurements is fundamental to perfecting your packaging. By understanding the importance of accuracy, leveraging appropriate tools and techniques, and implementing best practices, you can enhance your packaging processes’ quality, consistency, and efficiency. By bridging precision measurements with packaging design, you can create packaging solutions that protect and promote your products and elevate your brand image and customer satisfaction.